Nano Foam by Hard & Shine Chemicals is a premium-grade protein-based foaming agent specially designed for the production of CLC (Cellular Lightweight Concrete) blocks. Developed through advanced chemical engineering, Nano Foam delivers stable, fine, and uniform foam bubbles that result in lightweight, thermally insulated, and high-strength concrete blocks.

Whether you operate a small site-mix setup or a large-scale CLC plant, Nano Foam ensures higher yield, consistent quality, and cost efficiency.

Nano Foam produces foam with exceptional stability, allowing the bubbles to survive mixing and pouring without collapsing—critical for achieving uniform density in CLC blocks.

The foam forms microscopic, evenly distributed air cells that enhance compressive strength, thermal insulation, and acoustic performance in CLC products.

Only a small quantity of Nano Foam is required to produce large volumes of foam, making it extremely cost-effective.

Nano Foam enables accurate control over block density (from 600 kg/m³ to 1800 kg/m³), making it suitable for walls, partitions, insulation, and structural components.

Made from biodegradable protein compounds, Nano Foam is non-toxic, safe for workers, and aligned with green building practices.

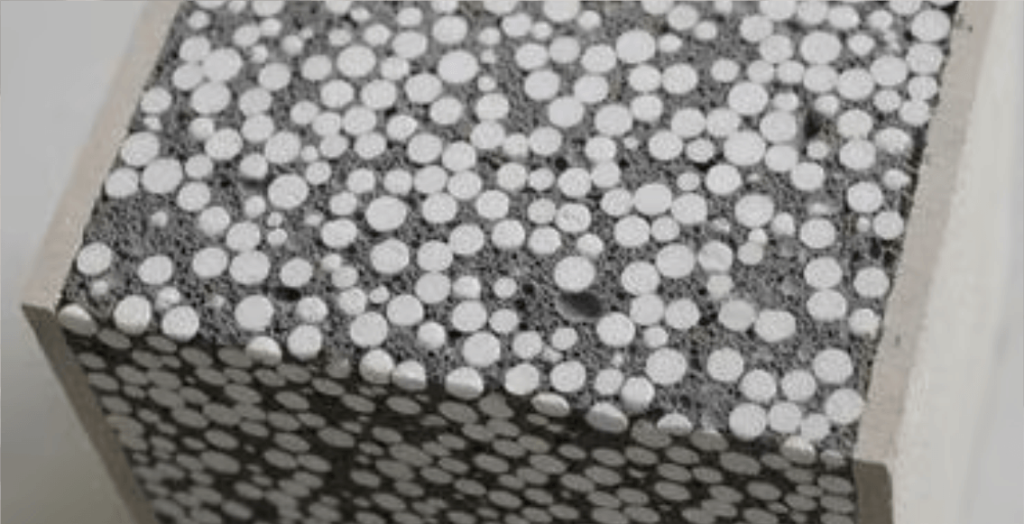

EPS Admixture by Hard & Shine Chemicals is a specially formulated polymer additive designed to enhance bonding, consistency, and performance in EPS (Expanded Polystyrene) concrete applications.

In EPS concrete, lightweight thermocol beads are added to reduce density—but this also brings challenges like bead segregation, poor bonding, and low strength. Hard & Shine EPS Admixture solves these problems by acting as a high-performance bonding and stabilizing agent, making EPS-based concrete uniform, durable, and easy to work with.

The polymer matrix improves the grip of cement on EPS beads, ensuring that the beads are firmly embedded in the mix,not floating or separating.

Prevents thermocol beads from rising to the surface, which is common in regular EPS mixes. This results in a uniform density throughout the block or panel.

Strengthens the mix so you can use less cement while still achieving reliable compressive strength for non-structural applications.

Acts as a plasticizer to improve mix flow, making the mortar or concrete easier to pour, level, and shape.

The final product is not only light but also provides thermal insulation and better fire performance, especially for prefab structures.